How long does your sand castle last, built on the soft sand of the beach? It lasts until the big wave hits it and crumbles it to the ground. In the same way, when engineers try to build heavy buildings, bridges, and roads on weak soil, they are not just constructing soon-to-be-sinking buildings, but they are also putting a lot of lives at risk. Here comes the best technique to improve soil quality. Rigid Inclusions. Yes, you read it right! Rigid inclusions are underground superheroes that make sure that massive structures don’t end up crumbling into the earth. So let’s delve into the details of rigid inclusion foundation systems.

What Are Rigid Inclusions?

Rigid inclusions are vertical and stiff columns installed in soft or compressible soils to enhance their load-bearing capacity and stability. They are underground pillars that support heavy structures, serving as an important element in modern-day construction. Unlike regular piles, they don’t carry the load of structures alone. Instead, they divide the load between the soil and the inclusions below. They are typically made of cement, composite materials, or grout.

The Controlled Modulus Column (CMC)

Now, here comes the most efficient type of ground improvement technique: Controlled Modulus Column (CMC rigid Inclusions). When the soil is too soft to carry the load, engineers use this method, which not only improves the soil but also helps in settlement control. They are carefully designed to work with the surrounding soil, sharing the load and creating a dense and strong ground support. Being cost-effective, they are also environmentally friendly since they generate less vibration and soil waste. Moreover, their installation is quick and easy, which requires a minimum labor force and time.

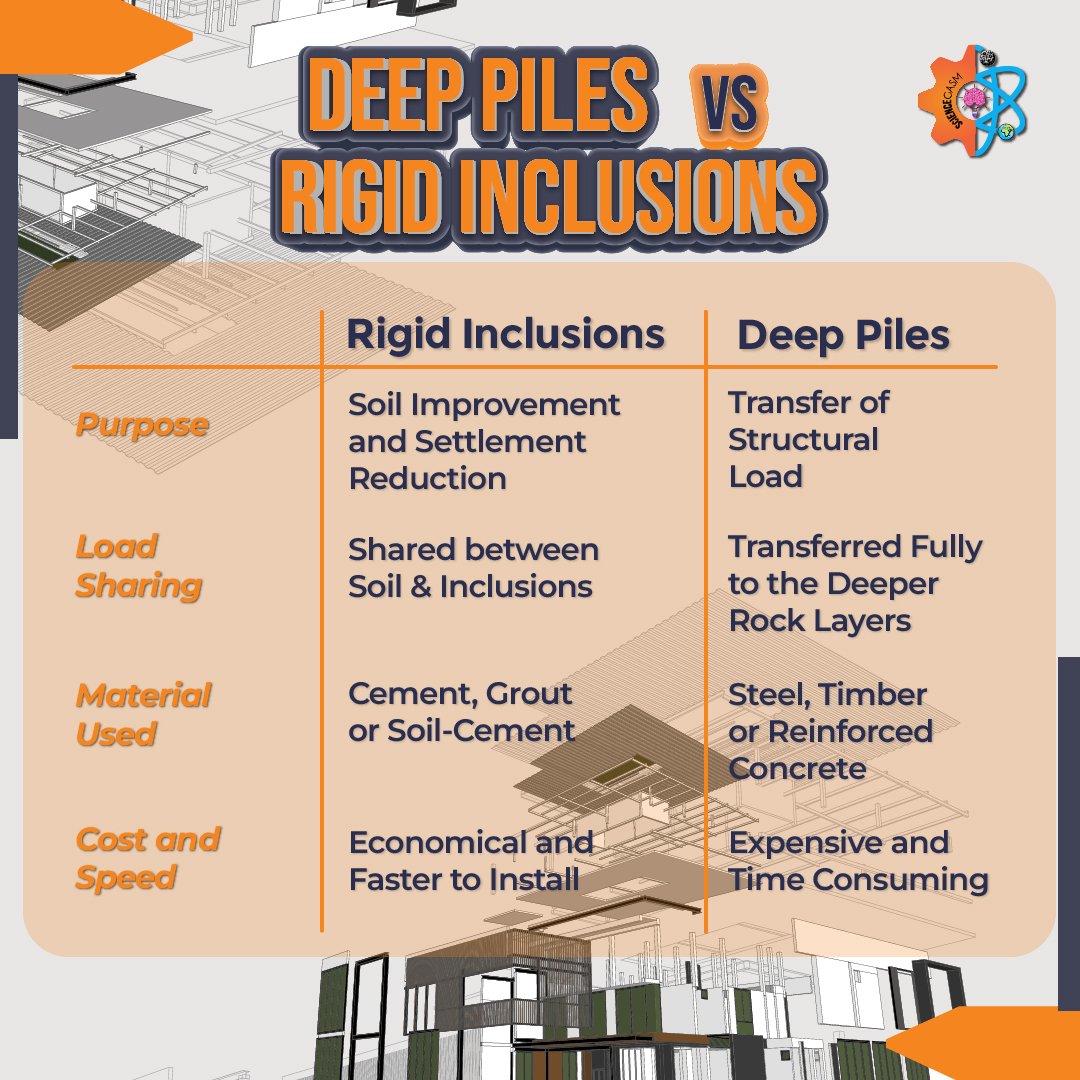

Rigid Inclusions v/s Deep Piles

The most common question often asked of an engineer is, How are rigid inclusions better than Deep piles? Deep piles are primarily used as structural support by transferring the entire load of the building to the deeper rock layers. Whereas, rigid inclusions team up with the surrounding soil, sharing the load through a Load Transfer Platform (LTP). On top of that, Deep piles are made of heavy materials like steel, timber, or concrete, which are not suitable for soft and weak soil. On the other hand, we use composite material for rigid inclusions like cement or grout, which ensures stiffness rather than overloading the soil. According to a recent case report, using rigid inclusions instead of deep piles can save up to 20% of the total cost.

How Do Engineers Install Rigid Inclusions?

Rigid inclusion installation is not an easy process. It requires a thorough soil analysis and site evaluation. If an engineer clears the site for installation, it is prepared, making space for machinery and inclusions to be installed. Here’s how the process of installation goes;

- Drill or Displace:

There are two ways for rigid inclusion installation: either by drilling through the ground or by displacing the soil using displacement augers or other machinery.

- Filling up:

Once the required depth is reached, the hole is then filled up using concrete, cement, or aggregated grout, forming rigid inclusion piles.

- Zone Testing:

Last but not least comes the most important part. Once the network of support columns is set, the zone is tested for its load-bearing capacity and strength.

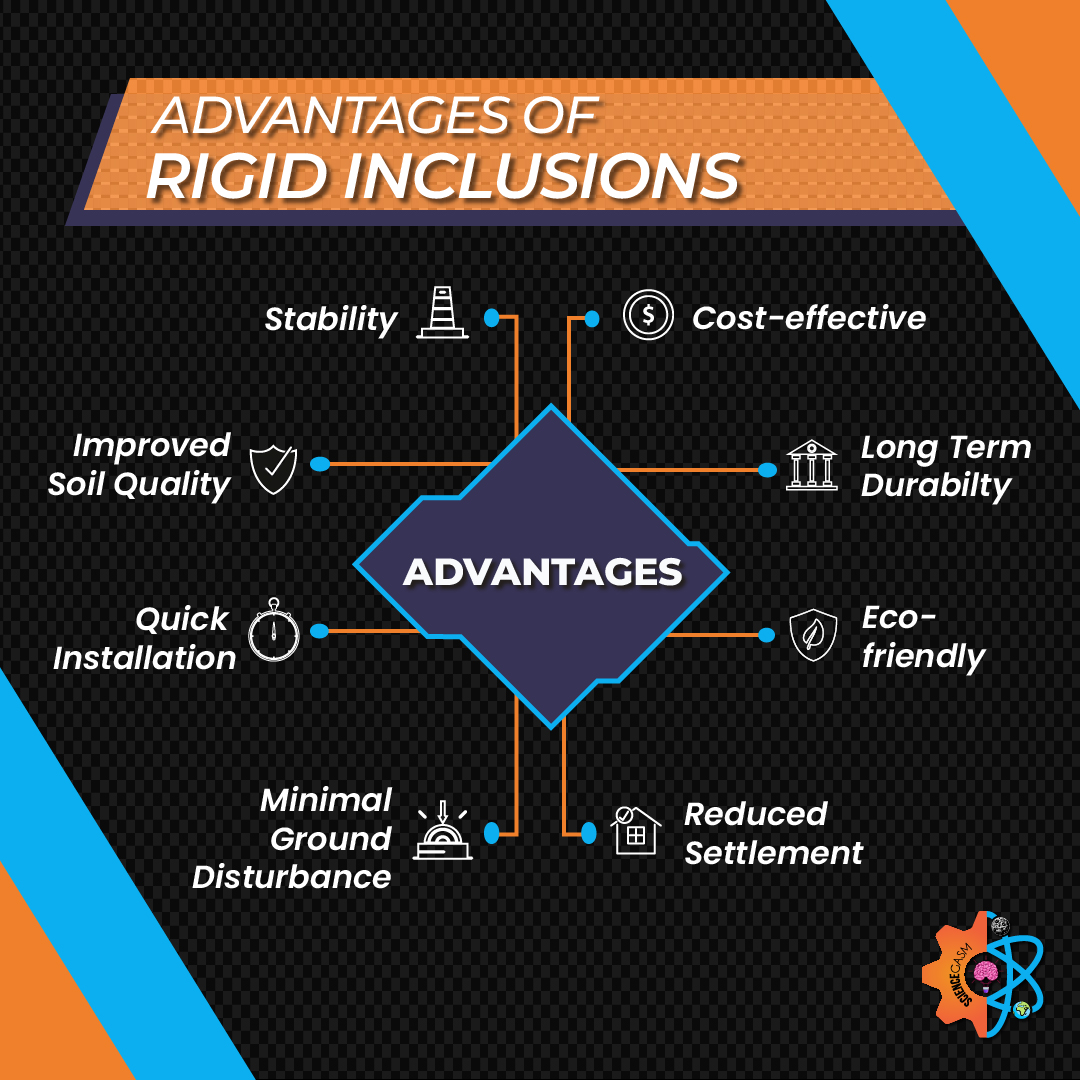

Applications and Advantages of Rigid Inclusions

Rigid inclusions are used widely across various sectors. Some of its common applications are,

- Supporting bridges and overpasses

- Constructing industrial buildings and transportation infrastructure

- Stabilizing flood protection embankments

Rigid Inclusions are important in geotechnical engineering, as they offer the following benefits;

- Improved soil quality

- Reduced settlement

- Cost-effective solution

- Quick installation

Limitations and Challenges of Rigid Inclusions

While rigid inclusions are useful for ground improvement, like any other method, they have certain drawbacks. Here are some common challenges faced by engineers when using this ground improvement technique;

- Rigid inclusions are best suited for soils that are soft and compressible.

- Their bearing capacity is limited.

- Rigid inclusions can reduce settlement, but cannot wipe it out entirely.

- Groundwater issues may hinder the installation process of rigid inclusions.

- It’s important to have the right diameter and depth of rigid inclusions. Moreover, maintaining a stiffness ratio of 40 to 50 between the columns and the soil ensures its effectiveness.

Ground Improvement Techniques

Not all soils are born with the strength to bear the load of massive bridges and buildings. Some soils are built differently, like soft soils such as clay or loose sand, which are weak and too risky. They need a support system that would help them increase their load-bearing capacity. These support systems are actually the ground improvement techniques that make soil tough and enhance its physical properties. Rigid inclusions are the most effective method of these. Some other techniques include;

- Soil Mixing:

Soil mixing, also called jet grouting, is a soil improvement method that involves the mixing of soft soil with cement or lime slurry, creating columns of soilcrete (grouted soil).

- Stone Columns:

These are vertical columns made out of stones or compacted gravel, installed in silty soils using a vibrating probe.

- Micropiles:

Micropiles are small-diameter elements, drilled and filled with steel or cement for transferring loads to stronger layers or underpinning the existing foundations.

- Soil Stabilization:

Soil stabilization involves chemical and biological processes to improve the mechanical properties of soil. Lime, polymers, and cement are some common additives used in this method.

Future of Soil Improvement

Soil plays a fundamental role in supporting massive skyscrapers and bridges built during the era of modern construction. Therefore, it is crucial to maintain its strength and bearing capacity. The methods we use today for soil improvement involve concrete or cement, which results in significant carbon emissions. In the future, we need to work with more sustainable and eco-friendly methods so that our future soil improvement not just makes our soil stronger but also greener. This includes using recycled aggregates, geopolymers, or slag instead of cement. In the next few decades, human intervention will be minimized with AI doing all the ground analysis and installation. With bioengineering and AI working hand in hand, the future of soil improvement is precise and science-driven.

Unseen Foundations Behind Modern Infrastructure

The world of construction has a long way to go in terms of some groundbreaking innovations to support the growing demand for skyscrapers, bridges, factories, and highways. Whether it’s rigid inclusion piles, stone columns, or CMC rigid inclusions, they all have one purpose, and that is to collaborate with the soil in creating a better construction foundation. Walking on the ground, we don’t even realize that there’s a whole big network of reinforcements, holding everything together for us.

Rigid inclusions play a big role in this. They are not just cement-made columns. They are the reason behind some remarkable buildings standing tall for decades. Hence, the real heroes are those who go unnoticed. Because rigid inclusions are not just making our present world better, but they are also making our future world greener and stronger.

Leave a Reply